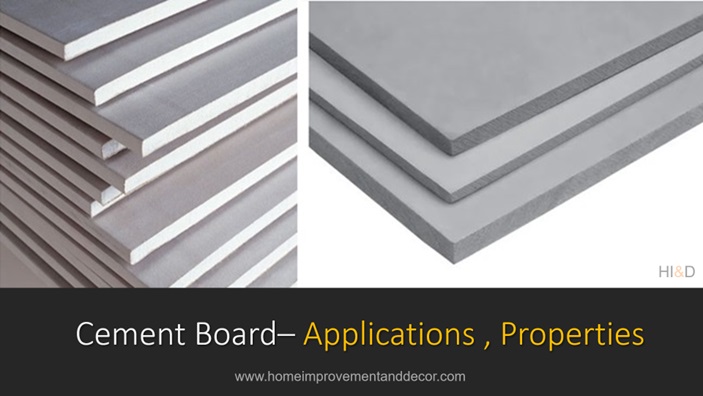

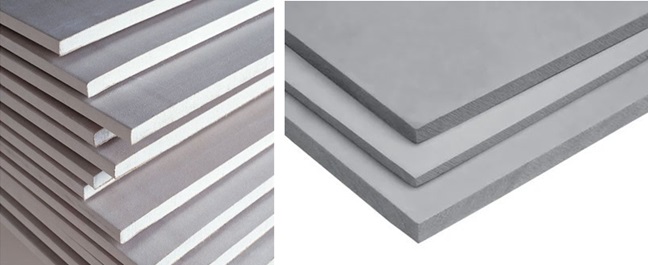

Cement Board

Cement Board is a type of wooden board manufactured using cement as binder. Learn more about Cement Particle board And Fiber Cement board.

Cement board is a type of wooden board that offer unique blend of some excellent properties suited for a wide range of applications.

It is made up of composite material manufactured either from cement-bonded particle boards or cement bonded cellulose fiber , silica and other fillers. Similarly, another type of cement board is also manufactured from cement and cellulose fiber that works as reinforcement.

Cement board derives its strength from cement-bonded particles, specially treated wood flakes, and cellulose fiber used as reinforcement. The cement provides structural strength and binds the wooden particles and cellulose fiber used as reinforcement material.

Both cement particle board and fiber cement board differ in composition. The cement fiber boards are manufactured from cement and cellulose fiber, which is a plant extract that is used as reinforcement.

In the realm of construction materials, cement board stands out as an unsung hero, quietly providing strength, durability, and versatility. Due to their unmatched properties, cement boards are extensively used for a wide range of applications. Often overshadowed by its more well-known counterparts like concrete and steel, cement board offers a unique set of properties and applications that make it indispensable in modern construction.

In this comprehensive guide, we will delve into the properties, applications, manufacturing process, and environmental considerations of cement board, shedding light on its importance and versatility in the construction industry.

Cement Board Types , Properties And Applications

Properties Of Cement Board

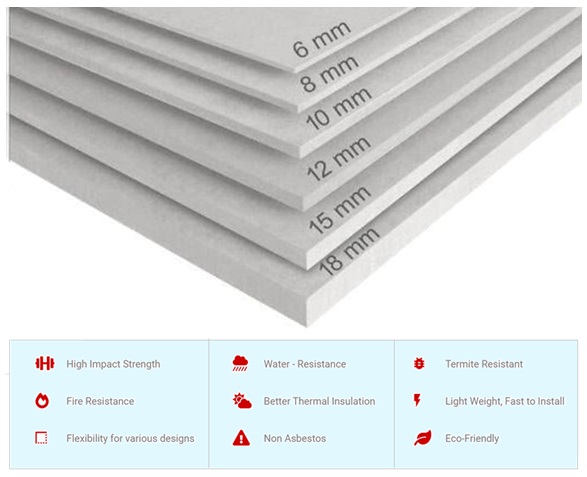

- Strength and Durability: Cement board is renowned for its exceptional strength and durability, making it ideal for applications requiring structural integrity and resistance to impacts, moisture, and fire.

- Moisture Resistance: Cement board exhibits excellent resistance to moisture, making it suitable for use in wet areas such as bathrooms, kitchens, and outdoor spaces.

- Fire Resistance: Cement board is inherently fire-resistant, providing added safety and protection in buildings, particularly in areas prone to fire hazards.

- Dimensional Stability: Cement board maintains its shape and dimension over time, resisting warping, swelling, and shrinkage even in harsh environmental conditions.

- Versatility: Cement board comes in various thicknesses and sizes, offering versatility in design and application. It can be easily cut, shaped, and installed to meet specific project requirements.

Applications Of Cement Board

- Interior Wall Cladding: Cement board is commonly used as an interior wall cladding material, providing a durable and moisture-resistant surface for areas such as bathrooms, kitchens, and utility rooms.

- Exterior Cladding: Cement board can be used as an exterior cladding material, offering protection against the elements while enhancing the aesthetic appeal of buildings.

- Floor Underlayment: Cement board serves as an ideal underlayment material for floor finishes such as tiles, hardwood, and laminate, providing a stable and moisture-resistant substrate.

- Roofing: Cement board is used in roofing applications to provide a strong and durable substrate for roofing materials such as asphalt shingles, metal panels, and clay tiles.

- Soffits and Fascias: Cement board is often used to construct soffits and fascias, providing a durable and low-maintenance solution for eaves and overhangs.

- Exterior Trim: Cement board can be used to create exterior trim elements such as window surrounds, door casings, and corner boards, offering enhanced durability and resistance to moisture and pests.

- Partition Walls: Cement board partitions offer a versatile and cost-effective solution for dividing interior spaces in residential, commercial, and industrial buildings.

- Backer Board: Cement board serves as an excellent substrate for tile and stone installations, providing a stable and moisture-resistant base for walls, floors, and countertops.

Manufacturing Of Cement Board

- Raw Materials: The primary ingredients used in the manufacturing of cement board include Portland cement, cellulose fibers, silica sand, and water.

- Mixing: The raw materials are mixed in precise proportions to form a homogenous slurry.

- Forming: The slurry is poured onto a conveyor belt or into molds, where it is spread evenly to form a thin sheet.

- Pressing: The formed sheet is passed through a series of rollers or presses to remove excess water and compact the material.

- Curing: The pressed sheets are cured in a controlled environment to allow the cement to hydrate and the board to harden.

- Finishing: Once cured, the cement board may undergo additional finishing processes such as sanding, cutting, and coating to achieve the desired surface texture and appearance.

- Quality Control: The finished cement boards are subjected to rigorous quality control measures to ensure compliance with industry standards and specifications.

Conclusion

In conclusion, cement board emerges as a versatile and indispensable building material, offering a unique combination of strength, durability, highly water resistant and versatility for a wide range of construction applications.

From interior and exterior cladding to flooring underlayment and roofing, cement board plays a crucial role in enhancing the safety, durability, and aesthetic appeal of buildings.

While its manufacturing process and environmental impact pose challenges, ongoing efforts to improve efficiency, reduce waste, and mitigate environmental emissions are essential for promoting sustainability in the cement board industry.

As construction practices evolve and demand for durable and sustainable building materials continues to grow, cement board remains a steadfast ally in the quest for safer, more resilient, and environmentally responsible built environments.