Construction Material - Cement

Applications , Types And Technical Properties Of Cement

Cement is a type of adhesive material used in the construction industry for binding other materials together. Cement is sold in power form and packaged in water-proof bags. Cement is also alternately referred to as ordinary Portland cement (OPC) or simply Portland cement.

General-purpose cement is a fine powder, typically grey in colour, that is made from a combination of limestone, clay, and other minerals. These minerals are processed and heated at high temperatures in a kiln, and the resulting product is called clinker. The clinker is then ground into a fine powder to produce cement.

Cement is extensively used in the construction industry as a binder or adhesive. The most common use of cement includes plaster work on brick masonry and concrete surfaces, and it is one of the key ingredients in producing concrete.

In order to activate the binding property of the cement, it should be mixed with water in the recommended proportion. When water is added to the cement, a chemical reaction called hydration starts. Hydration is an exothermic process that converts cement into a hardened mass.

Cement is a versatile building material that is extensively used to manufacture cement-based products such as tiles, paver blocks, cement pipes, and other such products. Different types of cement are available on the market depending on their chemical composition and properties.

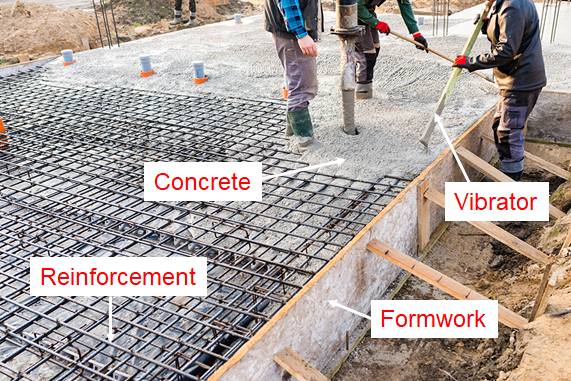

For example, concrete is prepared by mixing together cement, fine aggregates (Sand), coarse aggregates (Gravel), and water in the required proportion. The hardening of concrete starts when cement comes into contact with water and binds the aggregates (such as sand, gravel, and crushed stone) to form hardened concrete.

In addition to water, cement also requires the presence of aggregates and other supplementary materials such as sand and gravel to create concrete. These materials provide strength, durability, and other desired properties to the final product. Cement plays a crucial role in construction by providing the binding properties necessary to create strong and long-lasting structures.

All cement-based products, materials, and construction elements such as plaster, concrete, and cement flooring must be covered for the first few weeks to preserve their internal moisture. This process is called curing cement. The hardening of cement continues only in the presence of water added during the initial stage. Cement gains its complete strength after it is fully cured.

The civil engineering terminology is a ready reckoner that includes the definitions of various technical terms used in the construction industry and home improvement DIY projects.

Civil Engineering Terminology - Cement

Types Of Cement

Different types of cement are used in the construction industry, each with specific properties and applications. Some of the most commonly used examples of types of cement include general-purpose cement and special-purpose cement. The selection of cement type depends on factors such as project specifications, desired strength, durability requirements, environmental considerations, and local availability.

Here are some commonly used types of cement:

1. Ordinary Portland Cement (OPC)

OPC is the most widely used cement type in the construction industry and home improvement projects. It is available in different grades, such as OPC 33, OPC 43, and OPC 53, indicating the strength of the cement. Portland cement is a general purpose versatile product and suitable for various construction applications like general plaster and concrete works, foundations, flooring, grouting, and masonry.

2. Portland Pozzolana Cement (PPC)

PPC is a blend of OPC and pozzolanic materials, such as fly ash, volcanic ash, or calcined clay to alter certain properties of OPC. This type of cement provides higher durability, better workability, and reduced heat of hydration. PPC is suitable for hydraulic structures, marine construction, and mass concrete works where heat of hydration must be managed.

3. Rapid Hardening Cement (RHC)

Rapid hardening type of cement has a faster setting and hardening time compared to OPC. It is commonly used in situations where quick strength gain is required, such as in precast concrete elements, underwater repair works, and road construction. This is achieved by adding some special admixtures and finely grinding the clinker.

4. Sulphate Resistant Cement (SRC)

Sulphate Resistant Cement (SRC) is specially designed to resist the damaging effects of sulfates present in soil or water. It is used in areas where the soil or water has a high sulfate content, such as coastal regions or places with high groundwater sulfates.

Sulphate Resistant Cement (SRC) is a type of cement specifically designed to withstand the detrimental effects of sulfates present in soil or water. Sulfates can react with certain minerals in cement, causing expansion and deterioration of concrete structures over time. SRC is formulated to minimize such sulfate attack and ensure the long-term durability of the construction.

5. Low Heat Cement (LHC)

Low Heat Cement (LHC) generates less heat of hydration during the hardening or hydration process. This makes it suitable for massive concrete structures where considerable heat build-up during the hydration process that could lead to cracks. LHC is commonly used in dams, large foundation works, and mass concreting where large quantity of concrete is used with sizeable thickness.

6. White Cement

White cement is a type of cement that is specially manufactured to make it pure white in color. It is made from raw materials with low iron content, such as limestone and china clay. It has a white color and is primarily used for architectural purposes, decorative concrete, and finishing works where a lighter appearance is desired.

White cement is a type of cement that differs from ordinary gray cement in terms of color and composition. It is produced using raw materials with low iron content, such as limestone, kaolin, and white clay, which give it its distinctive white color. The manufacturing process of white cement is similar to that of ordinary cement, but with certain modifications to achieve the desired color.

Properties Of Cement

Cement possesses several important properties that contribute to its application and effectiveness as a construction material. These properties of cement make it a crucial component in the construction industry, allowing for the production of strong, durable, and structurally sound concrete structures.

Some key properties of cement:

- Setting and Hardening.

- Strength Development.

- Workability.

- Durability.

- Heat of Hydration.

- Fineness.

- Setting Time Control.

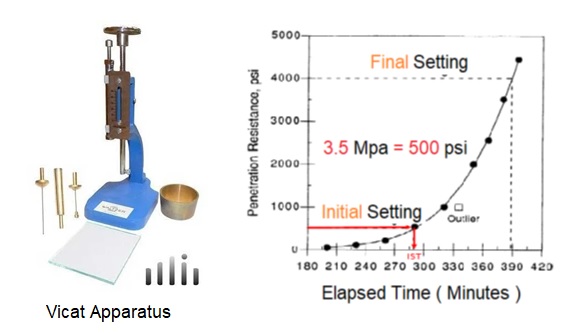

Setting Time Of Cement

Setting is an important property of cement that starts when it comes in contact with water. The setting of cement refers to the process by which cement, when mixed with water, undergoes a chemical reaction known as hydration. This results in the hardening and solidification of the material. This process is crucial for the strength and durability of concrete structures.

During the setting process the cement paste gradually looses its plasticity and moves from liquid or semiliquid state to solid state. The cement setting time is an important property that takes place in two stages. Two stages of setting time are initial setting time and final setting time.

Initial Setting Time

This is the first and early stage of the setting process that take place within 30 minutes after adding the water to cement. During this stage, the cement paste changes from a fluid, workable consistency to a stiff, solid-like state. The initial setting time is the time it takes for the cement paste to lose its plasticity and become resistant to indentation. It usually occurs within the first few hours after mixing cement with water.

Final Setting Time

This is the second stage of the setting and hardening process that takes place usually after initial setting and before 600 minutes when cement mixed with water. After the initial setting, the cement continues to harden and gain strength.

The final setting time refers to the point at which the cement has completely solidified and can bear some load without deformation. It usually occurs several hours after the initial setting, typically within a few hours to a day. The chemical responsible for the final setting time of cement is known as tricalcium silicate, or C3S.

Tricalcium silicate is one of the primary compounds found in Portland cement, which is the most common type of cement used in construction. The rate at which tricalcium silicate reacts with water determines the final setting time of cement.

Another important compounds in cement, tetracalcium alumino ferrite (C4AF), also contribute to the final setting time, but tricalcium silicate is the most significant compound responsible for final setting time.

Cement Type And Setting Time

Cement Type | Cement Grade | Initial Setting Time Minutes | Final Setting Time Minutes |

Ordinary Portland Cement ( OPC ) | 33 Grade | 30 | 600 |

Ordinary Portland Cement ( OPC ) | 43 Grade | 30 | 600 |

Ordinary Portland Cement ( OPC ) | 53 Grade | 30 | 600 |

Portland Pozzolana Cement ( PPC ) | 30 | 600 | |

Portland Slag Cement ( PSC ) | 30 | 600 | |

Rapid Hardening Portland Cement ( RHPC ) | 30 | 600 | |

High Alumina Cement ( HAC ) | 30 | 600 | |

Low Heat Cement ( LHC ) | 30 | 600 | |

Masonary Cement ( MC ) | 30 | 1440 |

Compressive Strength Development

Concrete Age After Casting | Compressive strength Development in Concrete |

1 Day | 16 % |

3 Day | 40 % |

7 Day | 65 % |

14 Day | 90 % |

28 Day | 99 % |

Chemical Composition Cf Cement

Cement is a widely used construction material that is composed of several key ingredients. The chemical composition of cement can vary slightly depending on the specific type and manufacturer.

In addition to these primary components, cement may contain small amounts of other compounds, including alkalis (sodium oxide and potassium oxide) and minor impurities.

It’s important to note that the exact proportions and chemical composition can vary among different types of cement, such as ordinary Portland cement (OPC), Portland pozzolana cement (PPC) , Rapid Hardening Cement (RHC) and Low Heat cement (LHC).

However, the most common type of cement, known as Portland cement, consists primarily of the following components:

- Calcium Oxide (CaO): Also known as lime or quicklime, it is derived from limestone (calcium carbonate) through a process called calcination. Calcium oxide contributes to the strength and durability of the cement.

- Silica (SiO2): Silica is obtained from materials such as sand, clay, and shale. It provides strength to the cement and is responsible for its binding properties.

- Aluminum Oxide (Al2O3): Aluminum oxide is derived from materials such as bauxite, clay, and fly ash. It contributes to the cement’s strength, hardness, and resistance to chemical attacks.

- Iron Oxide (Fe2O3): Iron oxide is obtained from iron ore. It gives the cement its characteristic color and also provides strength.

- Magnesium Oxide (MgO): Magnesium oxide is present in small quantities and is derived from materials such as dolomite. It affects the setting time and strength development of cement.

- Sulfur Trioxide (SO3): Sulfur trioxide is obtained from gypsum, which is added to regulate the setting time of cement.

How To Store The Cement ?

Storing cement properly is crucial to maintain its quality and ensure its usability for construction projects. By following these storage practices, you can preserve the quality and usability of cement, ensuring optimal performance in construction projects and minimizing material waste.

Here are some guidelines for storing cement:

- Dry Storage: Cement should be stored in a dry environment to prevent moisture absorption, which can lead to lumps or caking. Ensure the storage area is free from leaks, humidity, and standing water.

- Elevated Platform: Store cement on an elevated platform or pallets to prevent direct contact with the ground. This helps to avoid moisture absorption from the floor and minimizes the risk of contamination.

- Covered Storage: Protect cement from exposure to rain, sunlight, and other weather elements by storing it in covered areas, such as warehouses or storage sheds. Use tarps or plastic sheets to cover cement bags if stored outdoors temporarily.

- Proper Ventilation: Ensure adequate ventilation in the storage area to prevent the buildup of moisture and humidity. Good airflow helps to maintain optimal conditions for cement storage.

- First-In-First-Out (FIFO): Practice FIFO inventory management to use older batches of cement first. Label bags with their date of arrival and use them in the order they were received to prevent wastage due to spoilage.

- Secure Packaging: Keep cement bags tightly sealed to prevent air and moisture ingress. Use tape or plastic clips to reseal opened bags if not used entirely.