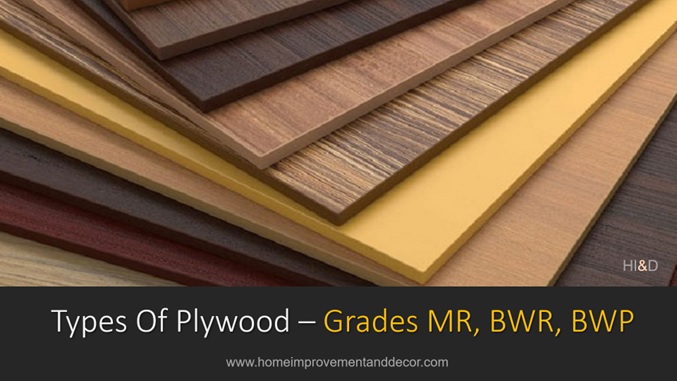

Types Of Plywood

How To Select Plywood ?

Plywood Buying Guide 2022

MR Grade , BWR Grade, BWP Grade , Commercial And Marine Plywood

Different types of plywood are used for various projects. Plywood is one of the most versatile building materials, extensively used in various interior design, building construction and home improvement projects. Plywood selection depends upon its strength, moisture resistance, termite resistance, and other properties.

Plywood sheets are manufactured by gluing and hot compressing several thin layers of natural wooden logs, called veneers, together. Special chemicals are used during the manufacturing process to impart the required properties to the plywood, such as moisture and termite resistance.

PLYWOOD TYPE | TYPE OR GRADE | PLYWOOD USE |

Moisture Resistant Plywwod | MR Grade | Suitable For Interior Projects. |

Boiling Water Resistant Plywood | BWR Grade | Suitable For Interior And Exterior Projects. |

Boiling Water Proof Plywood | BWP Grade | Suitable For Interior And Exterior Projects. |

Commercial Plywood | MR Grade | Suitable For Interior Projects. |

Marine Plywood | BWR , BWP Grade | Suitable For Interior And Exterior Projects. |

Plywood shops offer a wide range of options under different brands and grades. However, most people find the technical jargon used to identify various plywood types and grades confusing.

It is important for interior design professionals to understand various plywood types and grades to select the most suitable plywood for a specific application.

In this section, we will discuss in detail different types of plywood , grades , technical properties, and their applications in various interior and exterior design projects.

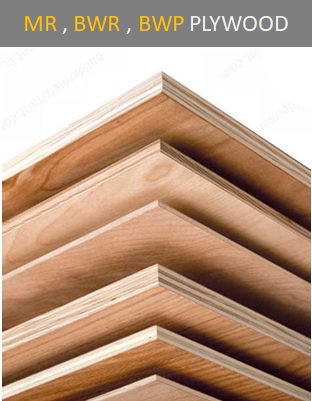

Plywood Types And Grades

Table Of Contents

- Moisture Resistant Plywood ( MR Grade ).

- Boiling Water Resistant Plywood. ( BWR Grade ).

- Boiling Waterproof Plywood ( BWP Grade ).

Plywood can also be categorized into ten different types as per its usage and properties. Different types of plywood are as follows:

- Interior plywood.

- Exterior plywood.

- Marine plywood.

- Commercial Plywood.

- Softwood Plywood.

- Hardwood Plywood.

- Structural Plywood.

- Aircraft Plywood.

- Flexible Plywood.

- Prelaminated Plywood.

Types Of Plywood For Interior Design Projects

MR Grade Plywood

Moisture Resistant Plywood ( MR Grade )

The moisture resistant ( MR ) plywood is the commonly used general purpose plywood. MR grade plywood is also alternately referred to as commercial plywood.

The MR grade plywood is the most affordable general-purpose plywood on the market, and it is best suited for dry areas. The MR grade plywood should not be used in moist conditions such as kitchen countertop base cabinets, bathroom remodel and furniture, or other such areas.

The MR grade plywood offers limited resistance to moisture. The MR grade plywood cannot withstand the sustained exposure to the moist conditions. The MR grade plywood also has limited termite resistance since it is structurally weaker as compared to BWR and BWP grade plywood.

The MR grade plywood is manufactured using urea formaldehyde, which is a type of synthetic resin used to manufacture the MR grade plywood. All commercial grade plywood need a special anti-termite treatment to augment termite resistance.

Applications Of MR Grade Plywood

- Plywood furniture placed in dry area.

- Bedroom wardrobes.

- Kitchen Cabinets.

- Partition walls.

- False ceiling work.

Types Of Plywood For Interior Design Projects

BWR Grade Plywood

Boiling Water Resistant Plywood ( BWR Grade )

The boiling water resistant ( BWR ) plywood is an exterior grade plywood. The BWR grade plywood is specifically manufactured to withstand exposure to water and termites. Superior quality wood plies and chemical binders give adequate strength to BWR ply to be used for both interior as well as exterior applications.

The BWR grade plywood is manufactured using a superior glue as compared to the moisture-resistant MR grade plywood. The BWR grade plywood is manufactured using phenol formaldehyde, which is a type of synthetic plastic resin used to manufacture the BWR grade plywood.

The phenol-formaldehyde resins are considered excellent wood adhesives and are used as binding glue for plywood and particleboard. It forms a chemical bond with the phenol-like lignin component present in the wood.

The phenol-formaldehyde resin imparts excellent water resistance properties to the BWR grade plywood. It is resistant to moisture and water exposure, making it ideal for use in wet areas such as bathrooms and kitchens.

BWR grade plywood can offer high moisture and water resistance much better than that of interior grade MR or moisture-resistant plywood. It can be used for furniture and other wooden work for both interior and exterior usage due to its superior water and termite resistance.

Applications Of BWR Grade Plywood

- BWR Plywood furniture placed in dry and wet areas.

- Suitable for bathroom furniture and cabinets.

- Kitchen countertop base Cabinets.

- Partition walls.

- False ceiling work.

- Outdoor furniture.

Types Of Plywood For Interior Design Projects

BWP Grade Plywood

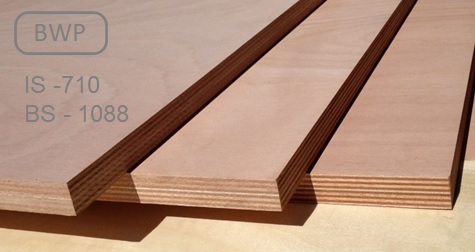

Boiling Waterproof Plywood ( BWP Grade )

The boiling waterproof ( BWP ) plywood is considered to be the best quality exterior grade plywood. It is referred as “Marine Grade” plywood. The BWP grade plywood as name suggest is specifically manufactured to withstand prolonged exposure to water and termites.

BWP plywood is manufactured with superior quality gurjan wood plies and chemical binders and resins imparts exceptional strength and water resistant properties.

BWP Gurjan Plywood is the premium quality, extra strong, and highly durable plywood made from wood veneers of Gurjan trees. Gurjan veneers are highly water resistant and strong. Gurjan Plywood stays exceptional among different grades of Plywood due to the extraordinary features it exhibits.

The quality of the BWP grade plywood can be tested by boiling the pieces of plywood. Good quality BWP plywood can easily withstand the boiling water test for a few hours without delamination or any visible deformity.

The BWP grade is basically a grade which defines the performance standards ( IS – 710 ) for either plywood or any other wooden board for water resistance and durability. BWP grade MDF, particle boards, and block boards are also available that can be used depending upon the project requirements.

BS 1088 Standard

British Standards For Marine Grade Plywood

British Standard are used world wide including US by marine plywood manufacturers as standard specifications for marine plywood. The plywood need not be manufactured by British Manufacture. It is an extensive document which details all the technical specifications for marine grade plywood.

The BS 1088 standard is a marine plywood specification that applies to plywood made from untreated tropical hardwood veneers that have a stated level of resistance to fungus growth.

BS 1088 plywood must use a glue, which has been tested and shown to be highly resistant to weather, micro-organisms, cold and boiling water, steam and dry heat.

Applications Of BWP Grade Plywood

- BWP Plywood furniture can be placed in dry and wet areas.

- Suitable for bathroom furniture and cabinets.

- Kitchen countertop base Cabinets.

- Partition walls exposed to moisture.

- False ceiling work.

- Outdoor furniture and wood work.

Types Of Plywood For Interior Design Projects

Exterior Plywood

What is exterior grade plywood ?

Exterior plywood is a type of plywood that can be used for external woodwork. External woodwork includes building external wall cladding, RCC formwork, outdoor furniture, and other similar works that are subjected to water, sunlight, and harsh environmental conditions.

The external grade plywood is specially treated to impart water and moisture resistance , UV resistance , termite resistance , heat resistance, and other such properties necessary to increase its durability and lifespan.

The BWR and BWP plywood , British standard BS 1088 grade marine plywood, are considered as exterior grade plywood.

Applications Of Exterior Grade Plywood

- External wall cladding.

- Outdoor furniture and cabinets.

- Garden Structures.

- Roofing Material.

Types Of Plywood For Interior Design Projects

Interior Plywood

What is interior grade plywood ?

Interior plywood is a type of plywood that is used only for internal woodwork. Internal woodwork includes building internal rooms, wall cladding, false ceiling work, indoor furniture, and other similar items that are not subjected to water, sunlight, and harsh environmental conditions.

The internal grade plywood offers limited moisture resistance, UV resistance , termite resistance , heat resistance, and other such properties. As a result, internal grade plywood is significantly less expensive than exterior grade plywood.

Applications Of Interior Grade Plywood

- Internal wall cladding for rooms.

- Indoor furniture, woodwork and cabinets.

- False ceiling work.

- Partition walls.

Types Of Plywood For Interior Design Projects

Softwood Plywood

What is softwood plywood ?

Softwood Plywood is a type of plywood that is made from softwood. It features a softwood veneer on the front and rear. Softwood plywood panels are constructed out of a softwood core.

Softwood Plywood is made from a variety of low-density softwood species like as Douglas fir, eastern white pine, balsam fir, ponderosa pine, redwood, spruce, pine fir, and others. It is structurally weaker than plywood since it is manufactured of low-density wood.

Softwood plywood is not suitable for high traffic or wear and tear applications.

Applications Of Softwood Plywood

- Construction Industry.

- Building Material.

- False ceiling work.

- Partition walls.

Types Of Plywood For Interior Design Projects

Hardwood Plywood

What is hardwood plywood ?

Hardwood plywood is made by gluing together many layers of hardwood material. The veneers on the front and back sides are made of hardwood. Deciduous trees such as birch, oak, mahogany, maple, teak, and beech are used to make the hardwood.

Hardwood plywood is a less expensive and more environmentally friendly alternative to typical solid wood building materials. It comes in a variety of grains, species, and grades.

Hardwood plywood is extremely sturdy and long-lasting. It comes in a range of thicknesses and in large sheets. The most typical hardwood plywood sizes are 4 × 8 feet, 3 x 6 feet, and 5 x 5-feet.

Depending on the manufacturer and type of plywood, the core can be constructed of any material, including softwood, hardwood, and composites.

Applications Of Hardwood Plywood

- Construction Industry.

- Building Material.

- Interior Furniture.

- Wooden Tiles Floor Base.