HPL Sheet

Elegant , Durable And Water Resistant High Pressure Laminate ( HPL ) Sheet

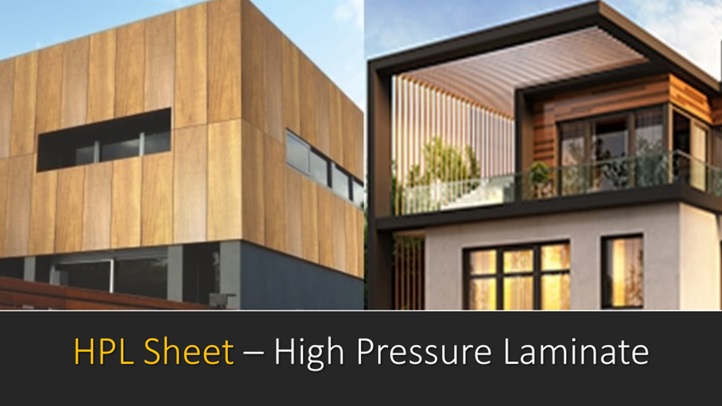

High Pressure Laminate HPL Sheet is an elegant, versatile, long-lasting, and water-resistant manufactured board. It is widely used in the construction industry for building facade cladding and other applications.

The HPL sheet is a highly durable material with excellent water resistance. Wood lookalike building façades, false ceiling work, outdoor gazebos and patios, wooden decks, and other such decorative applications are some of the most typical applications of high pressure laminates.

High pressure laminate is fast becoming the preferred choice instead of traditional building materials used for the treatment of exterior as well as interior building surfaces.

The installation process for HPL is also very simple and does not require any special equipment, materials, or highly skilled workmanship.

The HPL sheets are available in a wide range of colours, thicknesses, designs and technical specifications. It can be applied on both horizontal and vertical surfaces. The standard size of the HPL sheet is 8 X 4 feet and the thickness ranges from 6 mm to 10 mm.

The HPL sheets retains its color and design for a long time without any major repair or maintenance work. Most reputed brands offer product guarantee for five to fifteen years depending upon product grade and specifications. It can also be easily repaired, replaced and cleaned.

High Pressure Laminate HPL Sheet

Table Of Contents

High Pressure Laminate HPL Sheet

What Is HPL Sheet ?

HPL stands for High Pressure Laminate, and it is a type of manufactured wooden board used in the construction industry. Most building façades with elegant modern styles are created using HPL sheet.

High pressure laminate (HPL) offers an elegant look to the building. It is a versatile product with a wide range of applications in modern architecture. HPL sheet provides a durable, sophisticated, long-lasting, and water-resistant surface.

If you like wooden-finished, Swiss-styled buildings without the drawbacks and maintenance issues of wooden boards, then HPL sheet is the product. The durability and water-resistant properties of the HPL sheet make this material ideally suited for exterior building façade treatment.

The HPL sheets are manufactured by many leading brands that offer a wide range of colors, patterns, designs and textures. The wood design HPL sheet cut to plank size, on the other hand, creates a perfect wooden façade with stunning looks.

High Pressure Laminate HPL Sheet

How HPL Sheet Is Made ?

HPL sheets are manufactured by gluing multiple layers of kraft paper with phenolic resin under high pressure. The topmost layer of the HPL is made up of printed décor paper, which gives the color, design and texture.

During the manufacturing process, multiple layers of HPL sheet are fused together under intense heat and pressure (more than 1,000 PSI). The phenolic and melamine resins used to manufacture the HPL are thermoset plastics.

The curing process converts the resins into rock solid plastic by a cross-linking process that firmly binds the layers of paper sheets into a homogenous, sturdy, waterproof and durable laminated sheet.

The flexible CPL sheets offer a unique product that can be formed as per architectural requirements. Flexible HPL is produced from decorative paper impregnated with flexible thermosetting resins.

Multiple layers of paper with resins are fused under intense heat and high pressure. This engineered CPL offers a unique range of formable, flexible decorative laminates suitable for profile wrapping and edge bending applications.

High Pressure Laminate HPL Sheet

How To Install HPL Sheet ?

The HPL sheets can be installed by using different methods. Depending upon the project requirements, suitable method can be used. The three most common methods used for HPL installation include:

HPL Installation By Riveting.

In this method, the HPL sheet is first cut to the required size depending upon the architectural design. If you are planning a home improvement DIY project, then the riveting method is one of the easiest methods for HPL installation.

The aluminum section channels are used to create a substructure. The HPL sheet planks are installed on these channels using either a riveter tool or a Revit gun. Different colors of rivets are available to match the color shade of the HPL sheet.

HPL Installation Using Adhesives

Chemical adhesives can also be used to install HPL sheets. The installation process with adhesive is simple for the rear side ventilated facades and visible roof under faces. An aluminum channel section is used to create a substructure on which HPL is installed.

This method needs a 50x25mm rectangular aluminium channel, a 10×30 size SS screw, PU sealant, VHB structural glazing tape, and PU primer black etc. All the materials used, such as PU sealant and VHB tape, must be of good quality with resistance to UV radiation.

HPL Installation With Z-Clips

The third common method for HPL installation is by using a Z clip. In this method, the Z clip installation material consists of two parts. The first component of the Z clip, called the track, is fixed on the wall.

The second part of the Z clip is attached to the rear side of the HPL sheet planks. This second part of the Z clip is inserted from the top edge of the track fixed on the wall which holds the HPL planks.

High Pressure Laminate HPL Sheet

Applications Of HPL Sheet

HPL sheet is a versatile product and can be used for wide range of applications. However, due to its durability and water resistant properties, it is extensively used for exterior building surface treatment. HPL sheets are also used for interior applications.

- HPL Sheets Are Used For Building Façade.

- HPL Sheets Are Used For Garden Patio , Gazebo.

- HPL Sheets Can Be Used For False Ceiling Work.

- HPL Sheets Are Used For Waterproof Furniture.

- HPL Sheets Can also be Used For Roofing.

- It Is Suitable For Wooden Deck.

- HPL Sheets Are Used For Building Gates.

- It Can Also Be Used In Kitchen.

- It Can Be Used For Canopy Work.

High Pressure Laminate HPL Sheet

Advantages Of HPL Sheet

HPL sheets offer many advantages as compared to other alternate material. The HPL sheets are manufactured by many leading companies. Different types of HPL sheets with various features are available in the market.

- HPL Sheets Are Durable.

- HPL Sheets Are Water Resistant.

- HPL Sheets Can Be Easily Installed.

- HPL Sheets Are Long Lasting.

- HPL Sheets Require Less Maintenance.

- Wide Range of Colors And Designs.

- HPL Sheets Are Fire Resistant.

- High Impact And Abrasion Resistance.

- Flexible HPL Products Are Available.