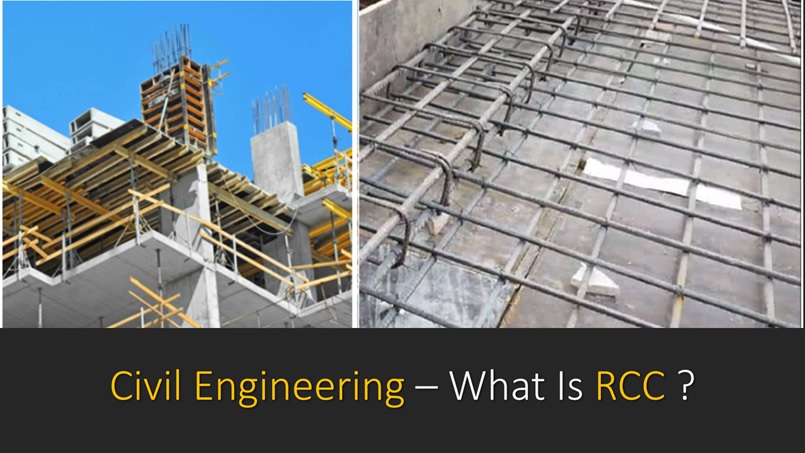

Reinforced Cement Concrete

Everything You Need To Know About RCC Structure

What Is RCC ?

What Is Reinforced Cement Concrete ?

The term “RCC” stands for “reinforced cement concrete. It is one of the most commonly used and versatile construction materials in the construction industry.

RCC structures are the most durable, economical, versatile, and long-lasting construction materials. The RCC is suitable for all types of buildings and infrastructure projects.

RCC is a composite material prepared from concrete and steel. The concrete is prepared by mixing cement, sand, coarse aggregates, and water in the specified proportion.

The reinforcement used in the RCC consists of hot rolled deformed bars ( HRDB ) and mild steel bars. The hot rolled deformed bars are used for the main reinforcement and the mild steel stirrups ( rings ) are used as sheer reinforcement.

RCC is a highly durable material that offers excellent compressive and tensile strength. It also offers some major advantages over other traditional materials, such as wood and steel.

RCC is the most versatile construction material and is extensively used for different types of structural components. The RCC structural members include foundations, column footings, slabs, columns, beams, fins, and other structures.

In this section, we will study RCC—reinforced cement concrete as a construction material; the properties of RCC; advantages and disadvantages of RCC structures; and design methodology.

Civil Engineering Basic Knowledge

Fundamentals Of RCC Construction

Table Of Contents

This section covers the basics of RCC – Reinforced Cement Concrete structures, properties, advantages and disadvantages of RCC.

Ingredients Of The Reinforced Cement Concrete

The RCC is prepared with two basic ingredients. RCC is a composite product made up of concrete and reinforcement. The most commonly used reinforcement in RCC work is steel bars.

The concrete is a mixture of cement, fine aggregates (sand), coarse aggregates (crusted stone) and water mixed together in the prescribed proportion as per the grade of the concrete.

The steel reinforcement consists of steel rods of the specific grade. The hot rolled deformed bars are used as the main reinforcement. whereas the mild steel reinforcement is used as sheer and distribution reinforcement.

The water used for the concrete mix must be clean and free from any chemical impurities. The water that conforms to the potable standard is considered to be safe for the RCC work. Water contamination can adversely affect the RCC strength.

The RCC structural design defines the grade of the concrete and the steel reinforcement to be used. The structural drawing is a part of the construction drawing set.

The use of ready-made concrete is extensively used for all types of reinforced cement concrete (RCC) projects. The ready-made concrete is produced under highly controlled conditions that conform to the specified quality standards.

Reinforced Cement Concrete - RCC

Advantages Of RCC Structures

The reinforced cement concrete offer some major advantages as compared to other construction materials.

- The RCC offers excellent durability.

- The RCC structure can be molded into any shape.

- The RCC structures are economical.

- The RCC structures requires low maintenance.

- The RCC structure is water resistant.

- The RCC structure can handle both compression and tension.

- The RCC is fire resistant.

- The RCC is frost resistant.

- The RCC structures are easy to construct.

Disadvantages Of RCC Structures

- The RCC structures are heavy.

- The RCC structure needs formwork.

- The RCC structure needs to be cured.

- The RCC structures can be used only after gaining full strength.

- The RCC structure cannot change its shape.

- The RCC structures requires skilled supervision.

Reinforced Cement Concrete - RCC

RCC Structure Design Basics

Different types of steel reinforcement bars and grades of concrete mix are used in the RCC work. The placement of the steel reinforcement into the RCC construction and the grade of the concrete mix depends upon the structural design.

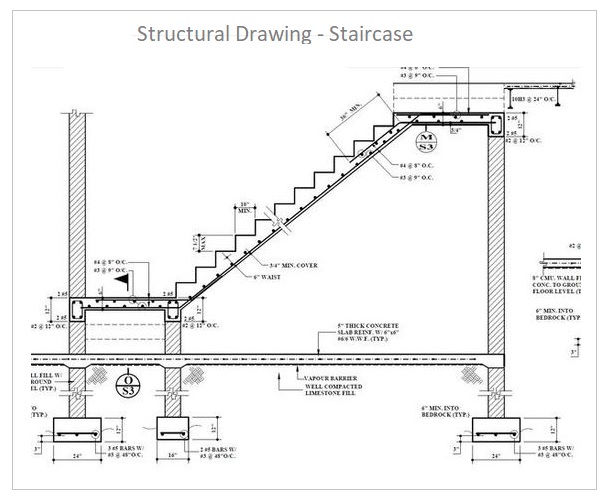

The structural design is a set of documents in addition to the construction drawings prepared by an architect. whereas the structural design is prepared by a licensed structural engineer.

The structural design of the building is a set of structural drawings that provide all the necessary information about the design details for each structural member.

The structural drawing provides the details of the placement of the reinforcement, type, size, and grade of the steel reinforcement bars. It also specifies the type and grade of the concrete to be used.

The structural components such as column footings, slabs, columns, and beams are required to be designed for both compressive as well as tensile strength.

Reinforced Cement Concrete - RCC

Properties Of RCC Structure

The reinforced cement concrete include following properties.

- The RCC has excellent compressive strength.

- The RCC has excellent tensile strength.

- The RCC structure has some ductile.

- The RCC structure is impermeable.

- The RCC structure has low coefficient of expansion.

- The RCC structure is not affected underwater.

- Generates heat of hydration.

What Is Reinforcement ?

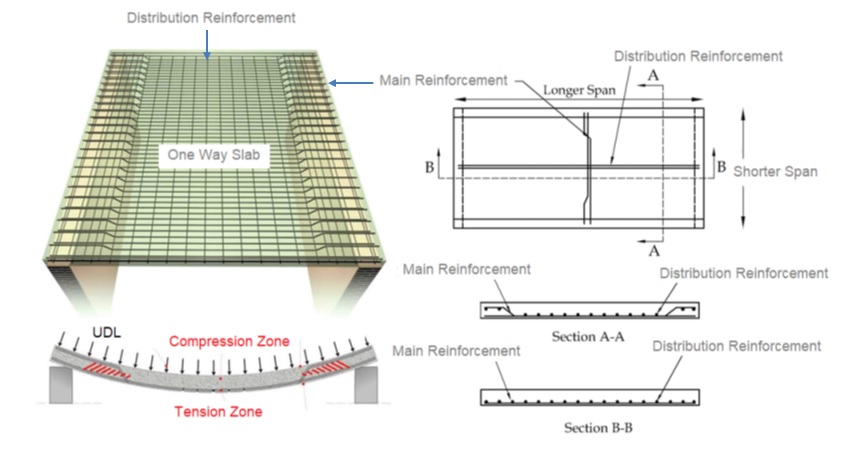

Plain cement concrete ( PCC ) provides excellent load bearing capacity in terms of its compressive strength. However, plain cement concrete is not considered very good in terms of tensile and ductile strength.

Therefore, in order to improve the tensile strength of the concrete, an additional layer of material called reinforcement is placed inside the concrete to handle the tensile stress. This composite concrete is called reinforced cement concrete ( RCC ).

Different types of reinforced cement concrete are used in the construction industry. However, steel reinforcement is the most widely used reinforcement material in RCC work.

Grades Of The Steel Reinforcement

Different types of reinforced cement concrete are used in the construction industry. However, steel reinforcement is the most widely used reinforcement material in RCC work.

Different grades of steel can be used as reinforcement for RCC structural work. The grade of the steel defines the tensile strength and other properties.

The American standard for steel reinforcement is specified in ASTM A 488. The European standard for steel reinforcement is specified in IDN 488.

The British standard for the steel reinforcement is specified in BS4449-97. The Indian standard for steel reinforcement is specified in IS 1786.

American Standard | European Standard | British Standard | Indian Standard |

ASTM A 615 | IDN 488 | BS 4449 - 1997 | IS 1786 |

Grade 75 ( 520 ) | BST 500 S | GR 460 A | Grade Fe – 415, Fe – 500, Fe – 500D |

Grade 80 ( 550 ) | BST 500 M | GR 460 B | Grade Fe – 550 |

Reinforced Cement Concrete - RCC

Placement Of Reinforcement

What Is Formwork In RCC Construction ?

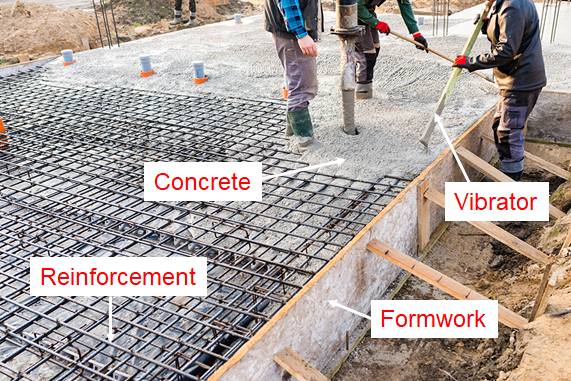

In order to construct an RCC structural member, a temporary mold is created as per the structural dimensions specified in the structural drawing. This temporary mold is called a “formwork.”

Different types of formworks are used in the construction industry to cast the RCC structural members such as column footings, columns, beams, retaining walls, and slabs.

A formwork is essential for the construction of the RCC structural work. After erecting the formwork, the steel reinforcement is placed inside the formwork as per the structural design.

The steel reinforcement rib is firmly secured in place with the help of cover blocks and the chair bars. The steel chair bars are specially designed to hold the reinforcement bars in place.

The final step is to pour the concrete into the formwork. The mechanical vibrators are used to compact the concrete mass. The compaction removes the air pockets and allows the concrete to flow easily into the formwork mold.

What Is RCC Design ?

Types Of Reinforcements In RCC Design

The term RCC design refers to the design of steel reinforcement designed by the structural engineer which also include the technical specifications, dimensions of the steel bars to be used for the construction of the RCC structural members under given loading conditions.

The structural design depends upon various design parameters such as dimensions of the RCC work , steel and concrete grade, loading conditions and other factors that affect the structural stability of the RCC work.

The main steel reinforcement (also referred as primary reinforcement) is placed in the concrete in the in the tension zone to handle the tensile stress. Whereas, the distribution reinforcement (also referred as secondary reinforcement) is placed to handle stress due to temperature changes.

Reinforced Cement Concrete - RCC

Types Of Reinforced Cement Concrete

Different types of reinforced cement concrete are used in the construction industry for different applications.

- Glass Fiber Reinforced Concrete ( GFRC )

- Steel Fiber Reinforced Concrete ( SFRC )

- Natural Fiber Reinforced Concrete ( NFRC )

- Polypropylene Fiber Reinforced Concrete ( PFRC )

- Engineered Cementitious Composite ( ECC )

The Chair And Cover In RCC

The reinforcement bars placed in the concrete are embedded in the concrete and should not be exposed. The reinforcement, if it gets exposed, can corrode, adversely affecting the strength of the structural member.

In order to protect the steel reinforcement bars from exposure, the cover blocks are placed at all the right places ( side and bottom surface of the formwork ).

The correct placement of the cover blocks ensures that the reinforcement is not exposed to the outside during the casting of the RCC structures.