Properties Of Cement

Learn Important Properties Of Cement And Concrete

Cement possesses several important properties that contribute to its application and effectiveness as a versatile construction material. These properties of cement depend on the chemical composition and manufacturing process used to produce it.

Cement properties also depend on the type of cement, since different types of cement are available on the market and are suitable for various applications. These properties make cement a crucial component in the construction industry, allowing for the production of strong, durable, and structurally sound concrete structures.

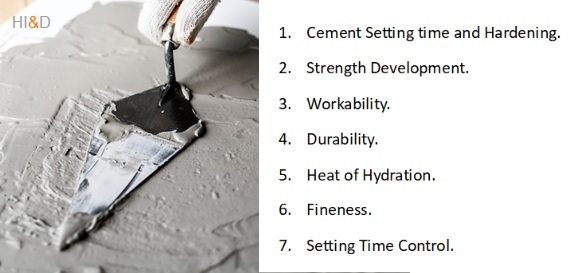

Some important properties of cement include:

Properties Of Cement

- Setting and Hardening.

- Strength Development.

- Workability.

- Durability.

- Heat of Hydration.

- Fineness.

- Setting Time Control.

The civil engineering terminology is a ready reckoner that includes the definitions of various technical terms used in the construction industry and home improvement DIY projects.

Civil Engineering Terminology - Properties Of Cement

Properties Of Cement

1. Cement Setting Time And Hardening

Setting is an important property of cement and cement products such as concrete. Cement has the ability to undergo a chemical reaction known as hydration when mixed with water. The chemical compounds present in the cement As a result, cement paste gradually loses its plasticity. This process leads to the setting and hardening of cement paste, resulting in the development of strength and rigidity over time.

The initial setting time refers to the time it takes for the cement paste to solidify. The initial setting time is usually 30 minutes. whereas the final setting time indicates the point at which the cement paste becomes significantly hard and cannot be further moulded. The final setting time is usually 600 minutes, barring a few specialised cements.

Cement Type And Setting Time

Cement Type | Cement Grade | Initial Setting Time Minutes | Final Setting Time Minutes |

Ordinary Portland Cement ( OPC ) | 33 Grade | 30 | 600 |

Ordinary Portland Cement ( OPC ) | 43 Grade | 30 | 600 |

Ordinary Portland Cement ( OPC ) | 53 Grade | 30 | 600 |

Portland Pozzolana Cement ( PPC ) | 30 | 600 | |

Portland Slag Cement ( PSC ) | 30 | 600 | |

Rapid Hardening Portland Cement ( RHPC ) | 30 | 600 | |

High Alumina Cement ( HAC ) | 30 | 600 | |

Low Heat Cement ( LHC ) | 30 | 600 | |

Masonary Cement ( MC ) | 30 | 1440 |

2. Strength Development

Compressive strength development is another important property of cement and concrete structures. Cement gains strength as it cures and ages. Curing of cement is crucial for strength development. The hydration process produces chemical compounds that contribute to the development of compressive strength in the hardened cement paste.

The strength of cement is typically measured in terms of compressive strength, which indicates its ability to withstand compressive stress or crushing forces. Compressive strength is one of the most important properties of cement.

It refers to the ability of cement to withstand compressive loads without undergoing deformation or failure. Higher compressive strength is desirable for applications where the cement needs to bear heavy loads or resist forces that tend to crush it.

Properties Of Cement

3. Workability

Workability of cement is another important property of cement. Workability refers to the ease with which cement can be mixed, placed, and compacted. It is an important property, especially during the construction process.

The workability of cement is influenced by factors such as water content, cement particle size distribution, and the presence of admixtures. Achieving the right balance of workability is crucial to ensure proper placement and consolidation of concrete.

It depends on factors such as water content, cement particle size distribution, and chemical admixtures. Cement with good workability can be easily molded, poured, and finished, making it easier to achieve the desired shape and surface finish.

Properties Of Cement

4. Durability

Durability is another important property of cement and concrete structures. Cement plays a significant role in ensuring the long-term durability of concrete structures. It provides protection against various environmental factors, including moisture, chemical attacks, and abrasion. The composition of cement, as well as the presence of supplementary materials or additives, can impact the durability of the hardened concrete.

5. Heat Of Hydration

Hydration is another important property of cement and concrete. The hydration process is an exothermic reaction in cement that generates heat. This heat of hydration can affect the temperature of concrete during the curing process. For massive concrete structures, the heat of hydration is a significant factor to consider.

Excessive heat generation can lead to thermal cracking, while low heat generation may be desirable in certain situations, such as massive concrete structures or in hot weather conditions. Cement types can be designed to have different heat and hydration characteristics to suit specific requirements.

6. Fineness Of Cement

Cement is finely ground to enhance its reactivity and workability. The fineness of cement refers to the particle size distribution and surface area. A higher fineness allows for better hydration and improves the strength development of cement. The fineness of cement is typically measured using the Blaine air permeability test or the sieve analysis method.

Fineness refers to the particle size distribution of cement. It is determined by the grinding process during cement manufacturing. Finer particles of cement have a greater surface area, which enhances the hydration process. Fineness also affects the workability, setting time, and strength development of cement. Fineness also affects the heat of hydration, and finer cement tends to produce more heat.

7. Setting Time Control

Cement undergoes a chemical reaction called hydration when mixed with water. The setting time of cement refers to the time taken for the initial setting and final setting of the cement paste. The initial setting time is the period when the cement starts to harden, while the final setting time is when it attains sufficient hardness to resist certain pressures.

The setting time affects the workability of cement and determines the time available for placing and finishing concrete. Cement can be formulated to have specific setting time characteristics to meet project requirements. Rapid-setting cement, for example, achieves an accelerated setting and hardening process, while delayed-setting cement offers extended workability time.