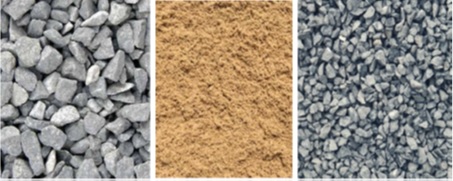

Types Of Aggregates

Different Types Of Aggregates Used As Construction Material. Basic Knowledge Of Aggregates For Home Improvement DIY.

Different types of aggregates are used as construction materials such as sand, gravel, crushed stones, and other recycled materials. Both fine and coarse aggregates are used to produce concrete, and cement mortar is extensively used in building construction and home improvement projects.

Aggregates are essential components of concrete and other construction materials. They are granular materials, typically made up of a combination of sand, gravel, crushed stone, and sometimes recycled materials.

Aggregates, such as crushed stone, gravel, and sand, provide strength and stability to construction materials. They form the bulk of concrete, which is a fundamental building material used in various structures.

Aggregates contribute to the load-bearing capacity of concrete, making it suitable for supporting heavy loads and ensuring the structural integrity of buildings, bridges, roads, and other infrastructure.

It’s important to select the appropriate type and quality of aggregates based on the specific requirements of the project. Factors such as particle size, shape, durability, and strength characteristics of the aggregates play a crucial role in the performance of the final construction material.

Aggregates play a crucial role in the construction industry and are widely used as construction materials due to their various important properties and benefits. Some different types of aggregates commonly used in construction.

Types Of Aggregates In Construction Material

Types Of Aggregates

Different types of aggregates are used in the building construction industry and other civil engineering projects. Aggregates can be broadly grouped into two types: fine aggregates and coarse aggregates.

1. Sand

Sand is a fine aggregate consisting of small granules of mineral particles. It is commonly used in concrete production, mortar, plastering, and as a bedding material for paving stones. The size of sand particles can vary, and different types of sand, such as river sand or crushed sand, may be used depending on the specific application. Sand must be granular and free from fine dust and clay to be used for construction purpose.

2. Gravel

Gravel is a coarse aggregate consisting of rounded or angular fragments of stones or rocks. It is commonly used in concrete production, road construction, drainage systems, and as a base material for foundations. Gravel is categorized into different sizes, such as 5mm, 10mm, 20mm, etc., based on the particle size.

Basalt a type of igneous rock is widely used as coarse aggregates. The size of the aggregate to be used depends upon the grade of the concrete and strength requirements.

3. Crushed Stone

Crushed stone is a versatile aggregate made by mechanically crushing rocks, boulders, or larger stones. It is commonly used in concrete production, road construction, and as a base or sub-base material for driveways and foundations. Crushed stone is available in various sizes, from fine dust (stone dust) to larger stones.

4. Recycled Aggregates

Recycled aggregates are obtained from the processing of construction and demolition waste. These aggregates include crushed concrete, crushed asphalt, and crushed brick. They are used as a sustainable alternative to natural aggregates, reducing the demand for virgin materials and minimizing waste.

5. Lightweight Aggregates

Lightweight aggregates are specifically manufactured to reduce the weight of concrete while maintaining its strength. They are typically made from materials such as expanded clay, shale, or slate. Lightweight aggregates are used in applications where weight reduction is important, such as in precast concrete elements or insulation concrete.

6. Slag Aggregates

Slag aggregates are obtained as a by-product from the iron and steel industry. They are formed during the smelting process and can be used as a partial replacement for natural aggregates in concrete. Slag aggregates offer various benefits, including improved workability, reduced permeability, and enhanced durability.

7. Natural Stone Aggregates

Natural stone aggregates, such as granite, limestone, or basalt, can be used in construction. These aggregates provide a visually appealing appearance and are often used in decorative concrete, landscaping, and architectural applications.

8. Graded Aggregate

Graded aggregates consist of a mixture of different sizes of aggregate particles. The combination of various sizes helps to optimize the packing density, workability, and strength of the concrete. Graded aggregates are commonly used in high-performance concrete, where precise control over the aggregate grading is essential.