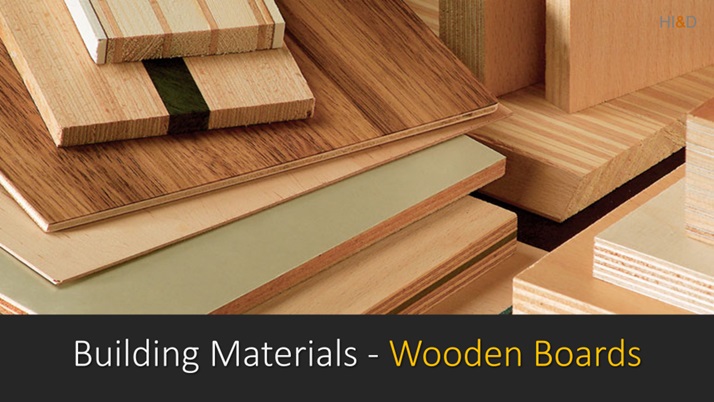

Wooden Boards

Different Types Of Wooden Boards Are Used For Interior Design, Furniture And Civil Projects.

Wooden boards are the most common and versatile building material and are extensively used for various building construction projects. The wooden boards are widely used in various home improvement, furniture, remodel, and other interior design projects.

Some of the most commonly used types of wooden boards include plywood, particle board, medium density fiber (MDF) board, WPC board, laminated board, block board, oriented strand board (OSB), and medium density particle board (MDP).

In this section will discuss different types of wooden boards, their technical characteristics, and their uses in interior design, furniture, and civil engineering projects. We will also discuss some latest entrants in building materials industry such as WPC boards , ACP boards and solid plastic boards.

Wooden Boards Types

Table Of Contents

Wooden Boards For Interior Design Projects

Plywood

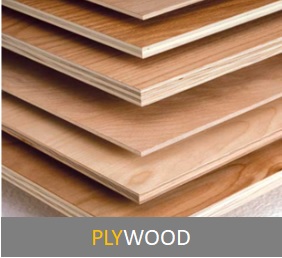

Plywood is the most commonly used form of wooden board. The plywood is manufactured in the factory by binding together thin slices of wood called plies or thin veneers with synthetic resin and adhesives.

The plywood quality depends upon the quality of the raw materials such as wood, chemical binders, manufacturing process, and other materials used to enhance the plywood quality and strength.

The plywood is manufactured by binding together multiple thin layers of wood veneer in their natural form. The wood fibers in the plywood are oriented in one particular direction, being made up of wood veneers.

Therefore, the plywood usually gives a better smooth cut if the cut is aligned in the direction of the wood fiber.

Different types of plywood are available on the market and used for different applications. The plywood types are differentiated based on the special features and their technical properties.

Applications Of Plywood

Plywood is a versatile and durable material that is available in different grades, strengths, and technical features. Plywood is extensively used for various applications such as furniture, base cabinet for kitchen countertops, cabinets, partition walls, false ceilings and other design features.

- Interior furniture and wardrobe.

- Kitchen countertops body and cabinets.

- Interior partition walls and false ceilings.

- Exterior grade plywood is used for outdoor work.

Plywood is one of the most commonly used building materials, extensively used in various interior design and home improvement projects.

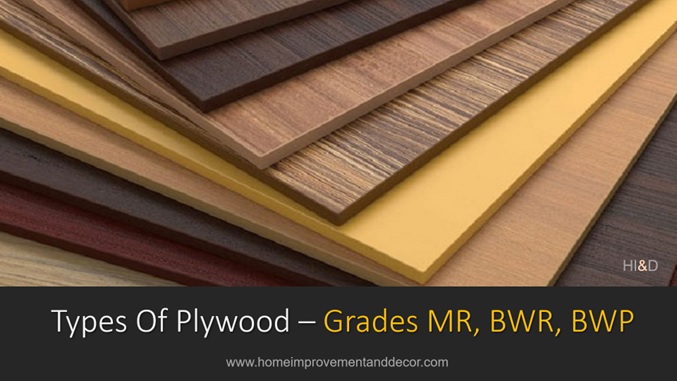

In the construction industry, different types of plywood are used for various applications. plywood is sold in three major categories, also referred to as “grades of plywood.” The three major types of plywood categories or grades include:

- Moisture Resistant Plywood ( MR Grade ).

- Boiling Water Resistant Plywood. ( BWR Grade ).

- Boiling Waterproof Plywood ( BWP Grade ).

Wooden Boards For Interior Design Projects

MDF Boards

Medium Density Fiber ( MDF ) Boards

The MDF board stands for medium density fiberboard (MDF), which is a type of engineered wooden board. The MDF boards are made of wood fibers glued together using some chemical adhesives and synthetic resin. This mixture is compressed under heat and pressure.

The MDF boards are manufactured in controlled conditions to produce a solid, durable board with a uniform thickness. The MDF boards are extensively used in the furniture industry as well as various building and interior design projects.

The MDF boards offer an excellent surface finish due to the random directions of the wood fibers used in the manufacturing process. And therefore, the MDF boards can be cut in any direction and gives a smooth finish cut. These boards are very easy to work with and can be molded in any shape.

The MDF boards are available in either plane boards and prelaminated MDF boards. The prelaminated boards are widely used in the readymade furniture industry. The MDF boards are mostly used for interior usage.

- Interior furniture and wardrobe.

- Kitchen countertops and cabinets.

- Interior partition walls and false ceilings.

HDF Boards

High Density Fiber ( MDF) Boards

The HDF board is an abbreviation for high density fiberboard (MDF), which is a better variant of the MDF engineered wooden board. In terms of strength and water resistance, HDF boards are considered to be superior to MDF boards.

HDF boards are manufactured from wood fibers and wood powder that have been bonded together with chemical adhesives and synthetic resin. In order to strengthen the water resistance capabilities of the HDF boards, some specific chemicals are also used.

This mixture is compacted using heat and pressure to create a board with a consistent thickness, superior surface finish and texture.

HDF boards are produced under controlled conditions to provide a solid, very durable, water-resistant board with a uniform thickness. When compared to MDF boards, HDF boards offer significantly better technical properties.

The HDF boards offer an excellent surface finish due to the random uniform material texture used in the manufacturing process. Therefore, the HDF boards can be cut in any direction and give a smooth finish. These boards are very easy to work with and can be molded into any shape.

- Interior furniture and wardrobe.

- Kitchen countertops and cabinets.

- Interior partition walls and false ceilings.

Wooden Boards For Interior Design Projects

Block Boards

Blockboard is also referred as Plyboard

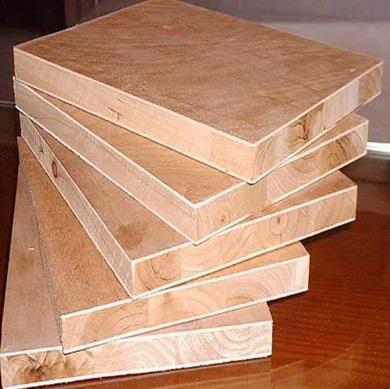

Block boards are also alternately referred to as plyboards. Plyboards are completely different products as compared to plywood. The block board is a special type of plyboard manufactured by placing a softwood block in between the two thin layers of wood veneers.

The strength of the blockboard depends upon the strength of the wood blocks used to manufacture the blockboard. However, the blockboard is considered a cheaper alternative to plywood.

Due to the limitations of the structural composition, blockboard (plyboard) cannot match the strength of plywood. However, plyboards are still used as a cheap, light weight material where strength is not required.

Plyboard can be safely used for wall panels , partition walls, book shelves, showcases, and door panels.

Particle Board

Low Density Fiber ( LDF ) Board

Different types of engineered wood products are used in various interior and exterior work projects for making furniture and other wooden items. Particle board is also one type of engineered wooden board extensively used for interior furniture products.

It is made up of wooden particles glued together with adhesives, synthetic resins, and other chemicals. It is also known as low-density fiberboard or chipboard.

Particle board is manufactured from waste wood products such as wood chips, sawdust, or sawmill shavings with a synthetic resin and chemical adhesives used to bind the material.

Particle boards are also called low-density fiber (LDF) boards. Due to its low density body, it is considered weaker as compared to MDF , HDF, and plywood. The larger sized wood particles are used to manufacture the particle board and the wooden chips can be clearly seen on the board edges.

Despite their limitations, prelaminated particle boards are used to produce low-cost furniture and other wooden board products.

Wooden Boards For Interior Design Projects

Flush Door

Flush Door Boards For Door Panels

The term “flush doors” refers to the door shutters manufactured from different types of wooden boards. The door sizes used for house construction and commercial projects are mostly standardized.

Various types of ready-made door shutters can be found in any home improvement or home décor store. These door panels are made up of different types of wooden boards, such as plywood, MDF, HDF, WPC and other forms of wooden boards.

The flush door panels usually have a wooden frame structure covered by surface veneer on both sides of the door. The internal wooden frame in the flush door provides the flexibility to make minor adjustments to the door size during fixing the door panel.

Further, the internal wooden frame in the flush doors provides the required strength to the door panel to hold the screws used to fix the door hinges.

Flush doors are available in various designs and finishes. Unfinished flush door panels can be customized and finished by fixing the laminates on both sides of the door as per the interior design.

Wooden Boards For Interior Design Projects

WPC Boards

Wood Plastic Composite ( WPC ) Boards

The term “WPC” stands for “wood plastic composite” board. WPC boards have gained popularity as they offer two major advantages as compared to natural wood, other engineered wooden boards, and plywood.

WPC board is a type of composite engineered board made up of wood powder, PVC particles, and plastic polymer. Its composition is 70% virgin polymer, 15% additive chemicals, and 15% wood powder.

Due to their durability and excellent water resistance properties, WPC boards are widely used for both interior and exterior design projects. It is available in three types, which include low-density, medium-density, and high-density WPC boards.

Due to its high moisture resistance, WPC boards can be used for bathroom furniture, kitchen countertop base cabinets, kitchen cabinets, and wall cladding. WPC board also offers excellent termite resistance, UV ray resistance, and durability. However, it is not a heat-resistant material.

HDHMR Boards

High Density High Moisture Resistant (HDHMR) boards

High Density High Moisture Resistant (HDHMR) boards are a type of engineered wood board designed to offer enhanced durability and high moisture resistance. These boards, due to their high durability and moisture resistance, offer a wide range of applications.

These are versatile boards and can be used for various applications in many industries, including kitchen platform bodies and counter tops, construction, interior design, and furniture manufacturing.

Learn more about High Density High Moisture Resistant (HDHMR) boards

HPL Sheet

High Pressure Laminate ( HPL ) Sheet

High Pressure Laminate (HPL) Sheet is an elegant, versatile, long-lasting, and water-resistant manufactured board. It is widely used in the construction industry for building facade cladding and other applications.

The HPL sheet is a highly durable material with excellent water resistance. Wood lookalike building façades, false ceiling work, outdoor gazebos and patios, wooden decks, and other such decorative applications are some of the most typical applications of high pressure laminates.

High pressure laminate is fast becoming the preferred choice instead of traditional building materials used for the treatment of exterior as well as interior building surfaces.

Learn more about High Pressure Laminate ( HPL ) Sheet

Softwood Board

What Is Softwood Wooden Board ?

Softwood wooden boards are versatile building materials known for their unique properties and wide-ranging applications in the field of interior design, furniture making, construction, carpentry, and various other industries.

These boards are manufactured from coniferous trees such as pine, cedar, fir, and spruce. As the name suggest, softwood boards are relatively soft as compared to hardwood boards and offer distinct advantages that make them desirable for a multitude of purposes.

Pinewood Softwood Board

Softwood Block Board

Since the core and inner body of these boards are made-up of softwood, one key property of softwood boards is their lightweight, easier to work with, which makes them easy to handle and transport, facilitating construction projects and woodworking projects.

Despite their soft raw material and lightweight, softwood boards offer impressive strength and durability, providing structural support and stability in building applications.

Further, softwood boards also offer excellent thermal insulation properties, making them ideal for use in wall panels, floor, and roof assemblies to enhance energy efficiency and comfort in buildings.

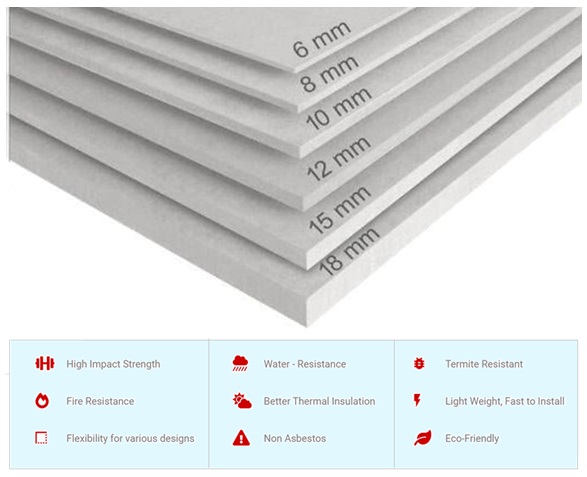

Cement Boards

Cement Particle Board And Fiber Cement Board.

Cement Board is a type of wooden board manufactured using cement as binder. Learn more about Cement Particle board and Fiber Cement board.

Cement boards are made up of composite material manufactured either from cement-bonded particle boards or cement bonded cellulose fibre board. Similarly, another type of cement board is also manufactured from cement and cellulose fibre that works as reinforcement.

Learn more about what is Cement board, properties, types and applications.