What Is Curing Of Cement ?

Types Of Curing Methods , Curing of Concrete And Its Importance Explained

The term “curing of cement” simply refers to maintaining the internal moisture and temperature so that the hardening process of cement is achieved. All cement-based construction materials, such as concrete, mortar, and slurry, need curing to gain their desired strength. Therefore, cement concrete must be cured to gain its full strength.

When water is added to cement or if cement comes into contact with water, chemical compounds present in the cement react with the water. This results in an exothermic reaction called the hydration of cement. It is the hydration process that is responsible for the hardening of cement into a rock-solid mass with good compressive strength. The hydration process is an exothermic process that generates heat called heat of hydration.

The term “curing refers to the process of maintaining favorable conditions necessary for the hydration reaction of cementitious materials, such as cement, to occur properly. Hydration is the chemical reaction between cement and water that results in the formation of a hardened material. Curing is an essential feature of all cement-based construction materials, and it allows cement to work as a binding material.

Curing is a crucial step in the concrete construction process as it helps achieve the desired strength, durability, and overall quality of the concrete. It involves providing sufficient moisture and temperature conditions to promote hydration and allow the cement to develop its full potential.

By providing optimal curing conditions, the concrete can achieve its desired strength, durability, and other performance characteristics. Properly cured concrete develops improved resistance to cracking, higher strength, and enhanced long-term durability, making it suitable for various construction projects.

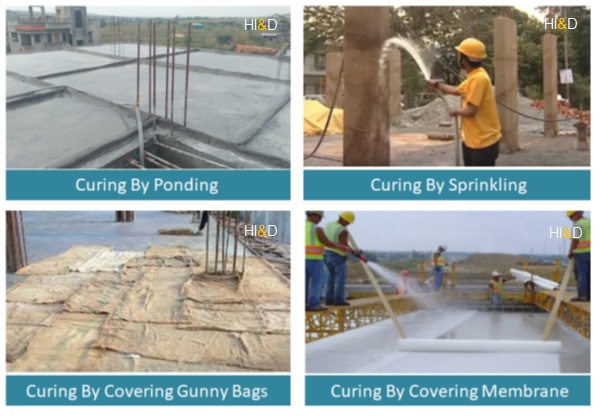

The most commonly used methods of curing include sprinkling water, covering with moist gunny bags, membrane curing, and some other methods that are also used under special conditions. Depending on the project requirements, a suitable curing method can be applied.

The civil engineering terminology is a ready reckoner that includes the definitions of various technical terms used in the construction industry and home improvement DIY projects.

Civil Engineering Terminology - Curing Of Cement

Essential Factors For Curing

Curing is essential component for all cement based construction material such as concrete , cement mortar, tiles and cement flooring work. Curing is a crucial step which allows cement to develop its full strength.

By providing optimal curing conditions, the concrete can achieve its desired strength, durability, and other performance characteristics. Properly cured concrete develops improved resistance to cracking, higher strength, and enhanced long-term durability, making it suitable for various construction applications. During the curing process, the following factors are essential:

1. Presence Of Moisture

Hardening of cement starts when it comes in contact with water. Therefore, adequate moisture is crucial for the hydration process. Various Curing methods help in preventing moisture loss from the concrete, ensuring that the hydration reaction continues uninterrupted. Methods to maintain moisture include ponding, sprinkling water , covering the concrete with moist gunny bags, plastic sheets, damp burlap, or using liquid membrane-forming curing compounds.

2. Maintaining Favorable Temperature

Temperature plays a significant role in the rate of hydration that imparts strength to the concrete. Depending upon site conditions suitable curing method can be used to manage the temperature changes. The curing temperature should ideally be within a favorable range, typically between 50°F (10°C) and 90°F (32°C). Extreme temperatures can adversely affect the strength development and overall quality of the concrete.

3. Duration Of Curing

Curing is essential for the cement to gain its full strength. Curing should be continued for a sufficient period to allow the concrete to develop full strength. The duration can vary depending on factors such as cement type, mixture proportions, ambient conditions, and desired strength requirements. Typically, curing lasts for a minimum period of 7 days, but recommended curing period is 28 days. However, longer durations may be necessary for specific site conditions and applications.

4. Protection

Sulphate Resistant Cement (SRC) is specially designed to resist the damaging effects of sulfates present in soil or water. It is used in areas where the soil or water has a high sulfate content, such as coastal regions or places with high groundwater sulfates.

Sulphate Resistant Cement (SRC) is a type of cement specifically designed to withstand the detrimental effects of sulfates present in soil or water. Sulfates can react with certain minerals in cement, causing expansion and deterioration of concrete structures over time. SRC is formulated to minimize such sulfate attack and ensure the long-term durability of the construction.

Types Of Curing Methods

Curing is an essential process for all cement related construction activities. It helps to ensure proper hydration and strength development of the concrete and other cement-based products. It’s important to note that the specific curing method used can vary depending on factors such as the type of cement, environmental conditions, and project requirements. Proper curing techniques are crucial to ensure the desired strength, durability, and performance of cement-based materials.

Some common methods of curing cement include:

1. Water Curing

This method is also called as water sprinkling method. Water curing is the most widely used method for curing cement structures. It involves keeping the concrete moist by spraying or ponding water on the surface. The main objective of this method is to preserve the internal moisture. This method prevents moisture loss from the concrete, allowing it to gain strength and durability. Water curing can be done using sprinklers, hoses, or by covering the concrete with wet burlap or plastic sheets.

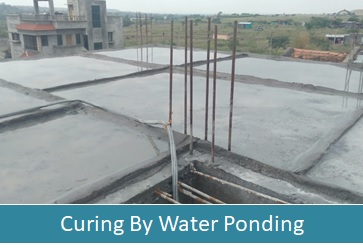

2. Water Ponding

The water ponding method is also commonly used, but it is suitable for small-scale construction projects. In this method, small ponds of 3 inches in height are constructed with lean cement mortar, and water is then poured into these ponds to achieve the desired curing. However, this method is suitable for only horizontal structures such as slabs and raft foundations.

3. Curing With Moist Gunny Bags

In this method, the cement structures, such as slabs, beams, foundations, columns, and other such concrete, are covered with moist gunny bags to achieve the desired curing. This method is very common, simple, and highly effective, suitable for small and large construction projects.

4. Steam Curing

Steam curing is a method used for accelerated curing of cement. It involves applying high-temperature steam to the concrete surface. Steam curing speeds up the hydration process and results in early strength gain. This method is commonly used in precast concrete production.

5. Chemical Curing

Chemical curing involves the use of chemical compounds that aids hydration and strength development. These compounds are typically sprayed or applied on the concrete surface. Chemical curing agents can help to reduce curing time and improve the overall quality of the concrete.

6. Membrane Curing

Membrane curing is a method that involves covering cement structures with a waterproof membrane on the concrete surface to prevent moisture loss. This method is commonly used in situations where water curing is not feasible or practical, such as in hot and dry climates. Membrane curing helps to maintain a moist environment and promote proper hydration.

7. Carbonation Curing

Carbonation curing is a unique method that utilizes carbon dioxide (CO2) to accelerate the curing process. Concrete is exposed to a high concentration of CO2 gas, which reacts with calcium hydroxide in the cement to form calcium carbonate. This reaction increases the strength and durability of the concrete.

Curing Of Concrete And Strength Development

Curing of concrete is a process that helps in maintaining adequate moisture and temperature conditions during the early stages after casting the concrete. It allowing concrete to develop its full strength and durability. Compressive strength development is a key aspect of concrete curing, as it refers to the ability of the concrete to resist compressive forces.

Concrete is a mixture of cement, coarse and fine aggregates, and water. During the hydration process, water reacts with cementitious materials in the concrete mixture, forming a hardened material that provides strength. Adequate curing is essential in first 28 days to ensure the hydration process occurs effectively and that the concrete reaches its desired strength.

Concrete Age After Curing | Compressive Strength Development in Concrete |

1 Day | 16 % |

3 Day | 40 % |

7 Day | 65 % |

14 Day | 90 % |

28 Day | 99 % |